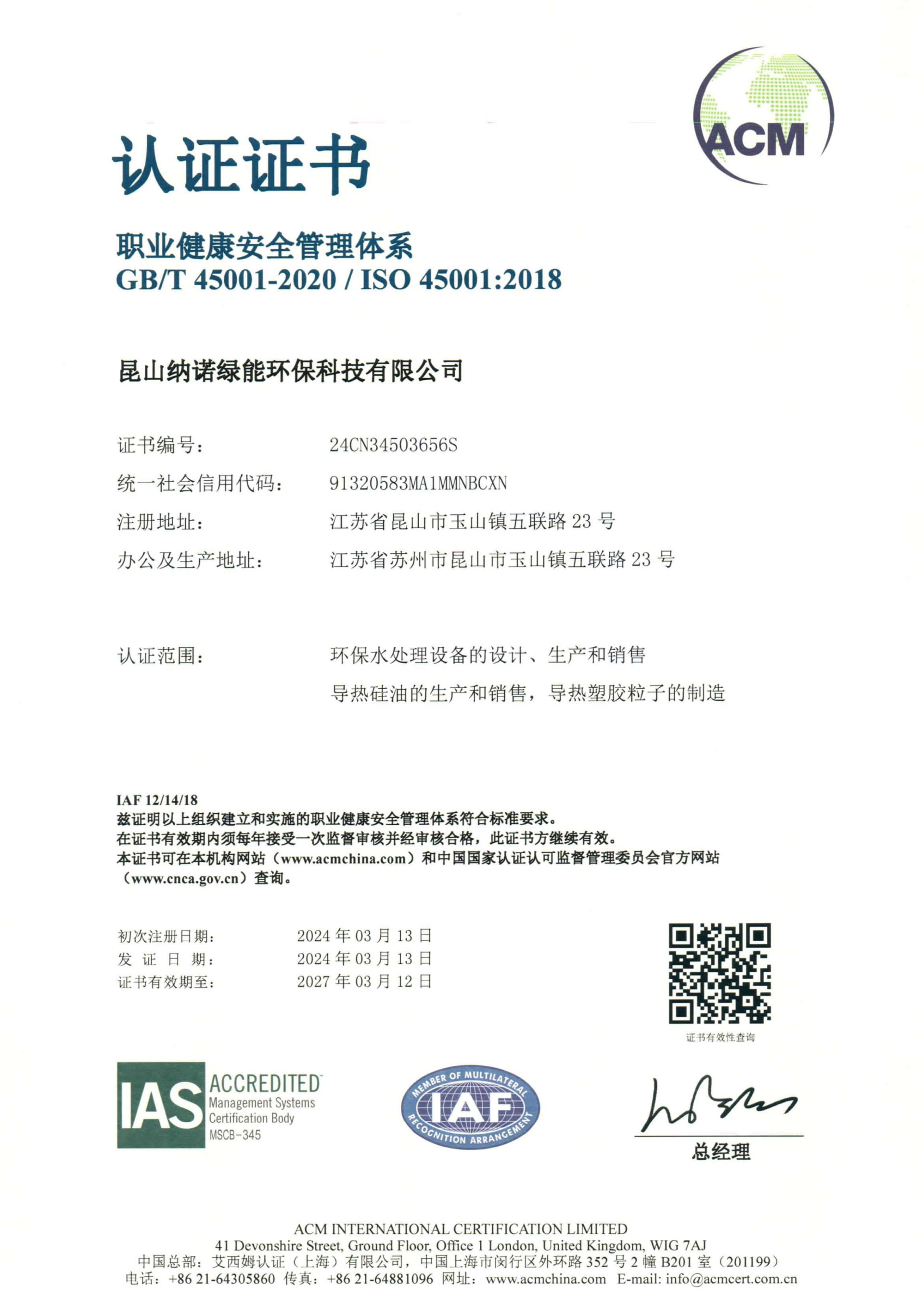

Reduced pressure and low boiling water separation technology

Reduced pressure and low boiling water separation technology

Professional skills

Features

Aerospace vacuum technology

Stirring drying technology

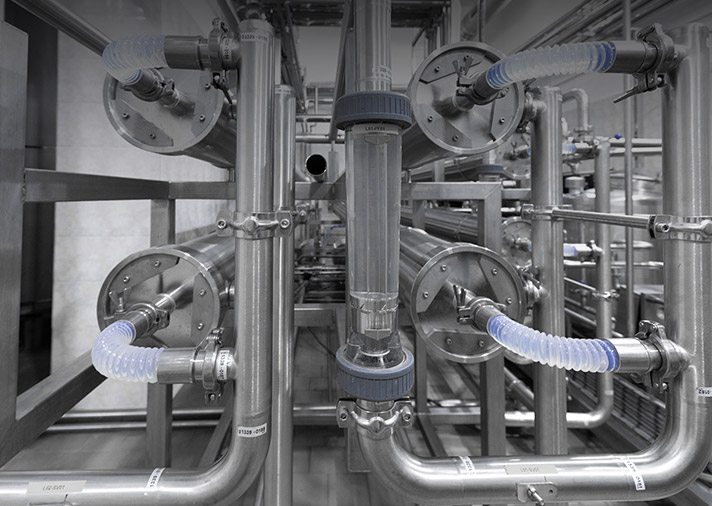

In a closed system, when the closed system is lower than atmospheric pressure, the boiling point of water will also decrease. Using the changing relationship between the system pressure and the boiling point of water, a distillation operation (liquid-liquid) or drying operation (liquid-liquid) under reduced pressure and low boiling can be obtained. liquid-solid), the separated water can be recycled after cooling. The traditional wastewater treatment process includes units or equipment such as pre-treatment primary sedimentation tank, coagulation sedimentation tank, digestion tank, concentration filtration and sludge cake treatment machine. Firstly, the time is too long and the demand for land is too large. In addition, chemical addition and water washing, etc. This results in an increase in sludge volume and higher operation and maintenance costs.

The company uses NRS equipment with reduced pressure and low boiling water separation technology to achieve the purpose of low-temperature distillation of industrial wastewater under reduced pressure and separate water from waste to achieve water recycling and reuse, emission reduction, land resource conservation and sludge reduction. The production volume is diverse for various purposes, especially for high-concentration waste liquid and sludge with high moisture content, the treatment efficiency can reach more than 90%.

NRS

advantage

Advantage

NRS reduced pressure low boiling water recovery equipment

Environmental protection and high economic benefits

The NRS water recovery and treatment system is used to desalinate seawater and separate seawater into two resources: fresh water and coarse salt. Unlike general concentration, which produces a large amount of brine and is discharged back into the sea, causing an increase in the concentration of seawater in local areas, it is environmentally friendly and Economic benefits

Good equipment versatility

The NRS water recovery and treatment system has a wide range of processing concentrations. It can not only directly treat seawater or high-salt wastewater desalination, but can also be used to treat brine produced by existing desalination equipment or other freshwater recovery processes without the need for any equipment. Structural changes, so versatility is excellent

Vehicle-mounted and highly mobile

The vehicle-mounted NRS water recovery and treatment system loads the equipment in a container truck and can be moved at any time. If it is equipped with an energy support vehicle and an independent power generation system, it can also be moved to places where fixed water, electricity and energy supply pipelines cannot be installed for operation, so it is mobile. Very strong

In addition to wastewater treatment, there are many liquid-solid drying operations such as PCB electroplating heavy metal waste liquid concentration, high COD waste liquid crystallization, seawater desalination, chemical industry acid and alkali waste liquid salt crystallization, and oil sludge/sludge drying. In addition, liquid-liquid distillation operations such as extreme concentration of organic solvents, extreme concentration of cutting fluids/grinding fluids/release agents, or water distillation from other high-boiling organic waste liquids/solvents are also common.

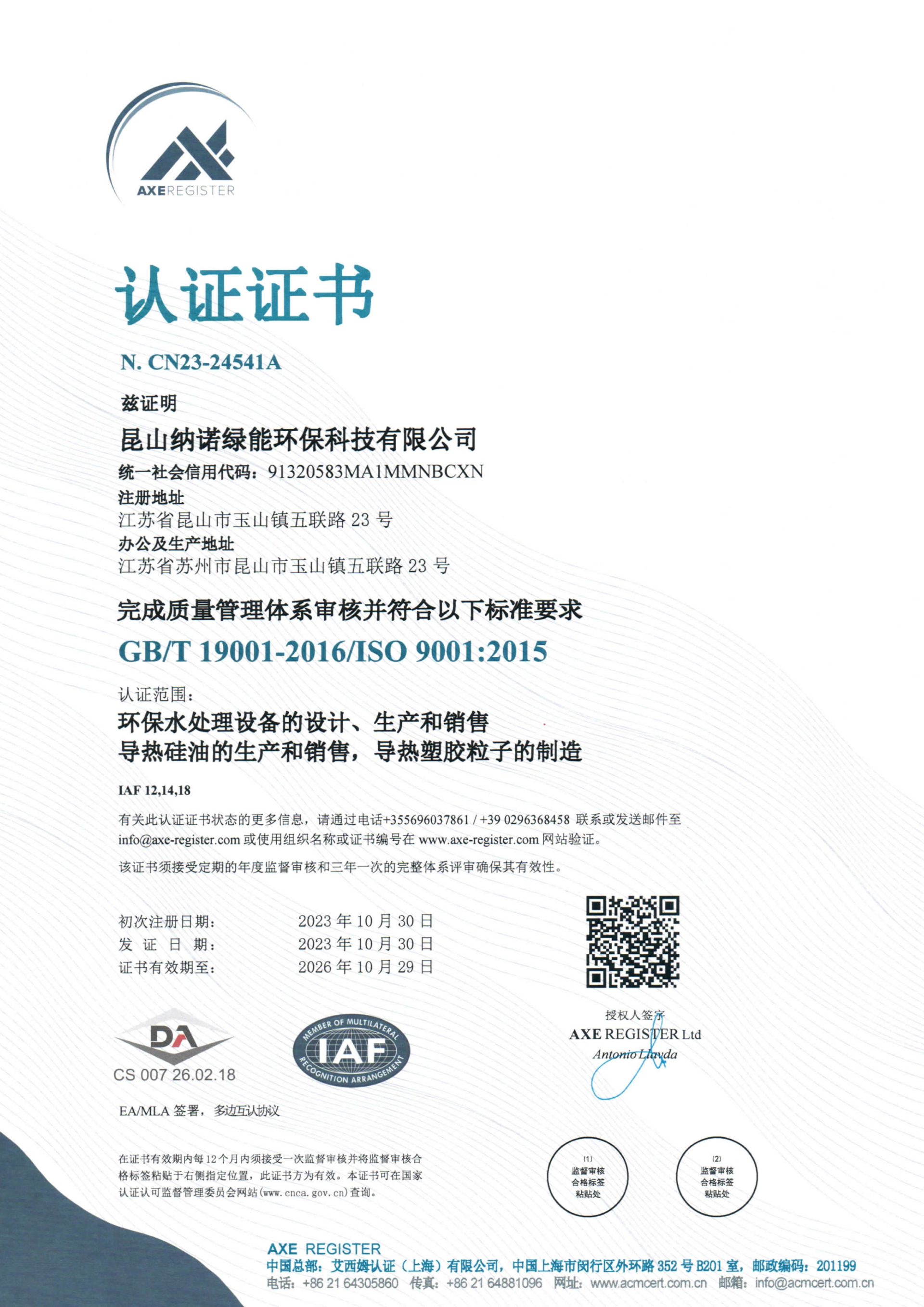

| No. | Name | Type | Application Number | Patentee | Application date | Authorization announcement number |

| 1 | A kind of reactor raw liquid pre-mixing device | Utility model | 2022213764827 | Kunshan Nano | 2022/6/5 | CN218281322U |

| 2 | A centrifugal solid-liquid separation device for sewage treatment | Utility model | 2021210390818 | Kunshan Nano | 2021/5/17 | CN215026744U |

| 3 | A detachable filter device for sewage treatment | Utility model | 2021210390748 | Kunshan Nano | 2021/5/17 | CN215026590U |

| 4 | A sedimentation barrel for waste liquid treatment that is easy to clean quickly | Utility model | 202120999990X | Kunshan Nano | 2021/5/11 | CN215026241U |

| 5 | A multi-pipe anti-clogging discharge device for sewage treatment | Utility model | 2021209999933 | Kunshan Nano | 2021/5/11 | CN215253282U |

| 6 | A kind of waste liquid treatment equipment | Utility model | 2021207267875 | Kunshan Nano | 2021/4/11 | CN215249672U |

| 7 | A water and gas separation device | Practical | 2021207052040 | Kunshan | 2021/4/7 | CN215026229U |

| 8 | A device for eliminating paint viscosity and squeezing and dehydrating paint sewage treatment | Utility model | 2020210198630 | Kunshan Nano | 2020/6/5 | CN212770188U |

| 9 | A kind of nano-microbubble waste gas treatment equipment for chemical plant sewage treatment | Utility model | 2020210188573 | Kunshan Nano | 2020/6/5 | CN212758028U |

| 10 | A decompression and low-temperature water separation equipment with high concentration efficiency | Utility model | 2019215539200 | Kunshan Nano | 2019/9/18 | CN210674259U |

| 11 | A kind of nano-microbubble waste gas treatment equipment for spraying plants | Utility model | 2019215539465 | Kunshan Nano | 2019/9/18 | CN210674692U |

| 12 | A kind of nano-microbubble waste gas treatment equipment for incineration plants | Utility model | 2019215539376 | Kunshan Nano | 2019/9/18 | CN210674600U |

| 13 | bubble generator | Utility model | 2020203087826 | Kunshan Nano | 2020/3/13 | CN212271109U |

Taiwan

Taipower (Xingda Factory)

Koyoko

AUO

Fengda Technology

Lianmao Electronics

Kewei

Beishi Chemical

Shanghai Silver Technology

Far east textile

Weili Food

Nordson Environmental Protection

China

Sichuan Galaxy Chemical

Changshu Polymer Chemistry

Foxconn Group

Nanjing Innolux Optoelectronics

Yantai resort car

Nanjing University of Technology Environment

Luxshare Precision

Jiangsu Yuanmao Environment

Kunshan Changyun Electronics

Koyo Chemical

Hefei Cement Research Institute

Formosa Plastics Group

CITIC Dicastal

Kunshan Nanya Electronics

Shandong Lukang Pharmaceutical

Wuxi Xinguangmai

Shandong Pentium Paint Industry

Service subject

Hongchao Environmental Protection Energy Co., Ltd. Go to link

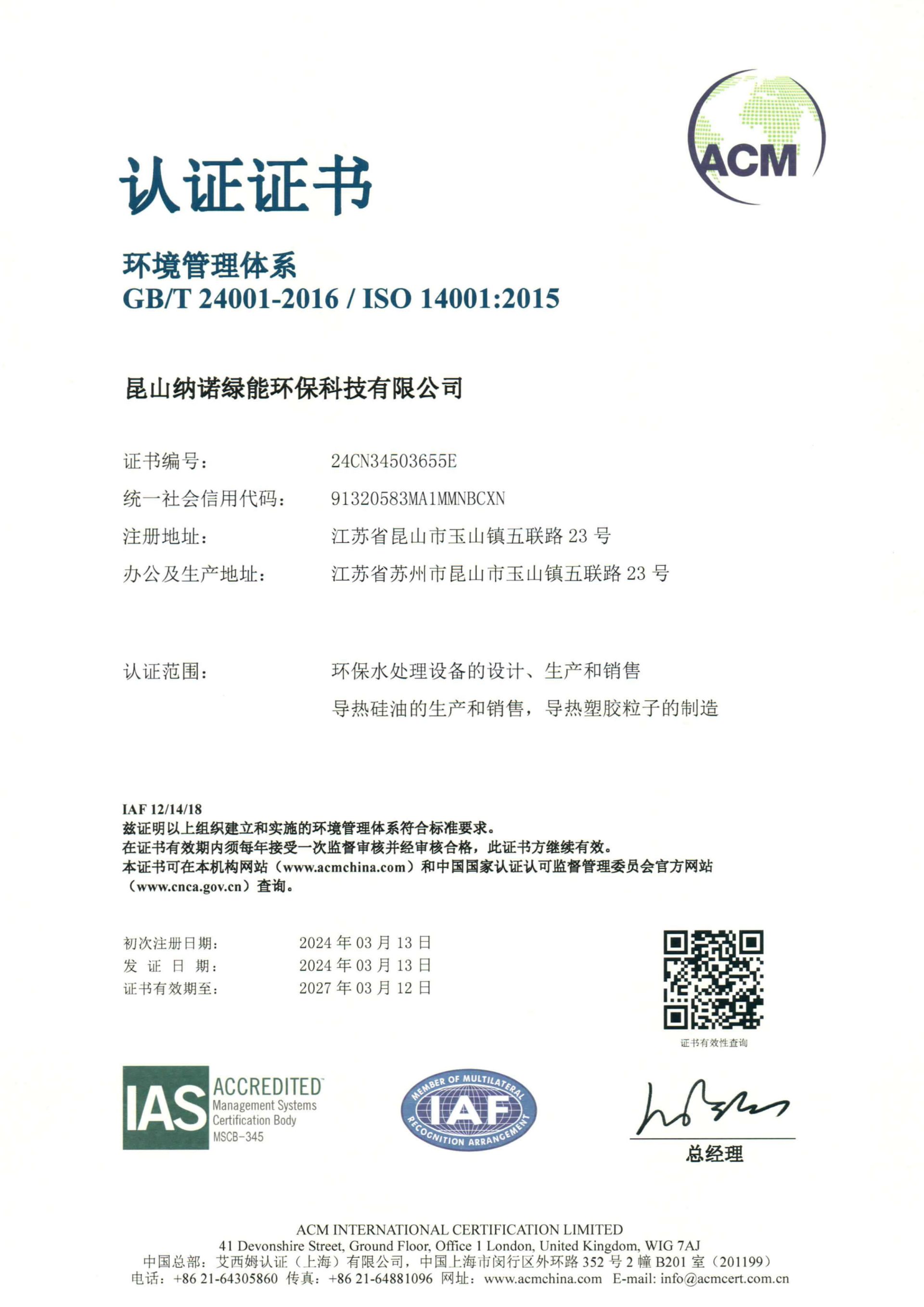

Kunshan Nano Green Energy Environmental Protection Technology Co., Ltd.Go to link

Service process and consultation

台灣

Case acceptance process

STEP1

Business briefing

STEP2

Small test and medium test

STEP3

Program planning

STEP4

Inquiry and quotation

STEP5

Bargain

STEP6

Sign a contract

STEP7

Procurement outsourcing

STEP8

Delivery and construction

STEP9

Completion debugging

STEP10

Warranty sales

Business representative:

China

Case acceptance process

- Contact the sales representative directly (contact window below)

- Add the company's WeChat account 18913148285 (same as WeChat account) for consultation, and then recommend corresponding services according to customer needs

- If customers have inquiries about information attachments, they can send them to the email lulu@nanoplustech.cn

Business representative:

North China: Chen Yanpeng 13176760766

East China: Zhu Qifeng 15850181618