High thermal conductivity heat dissipation material

High thermal conductivity heat dissipation material

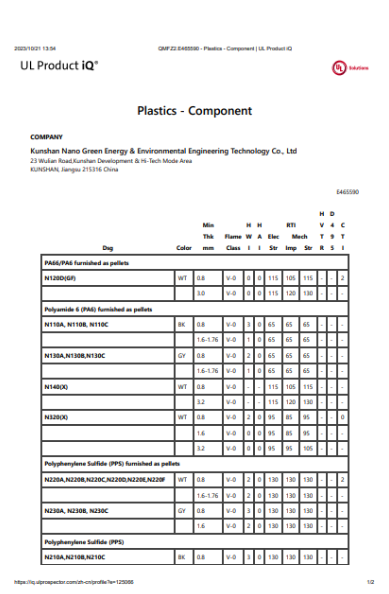

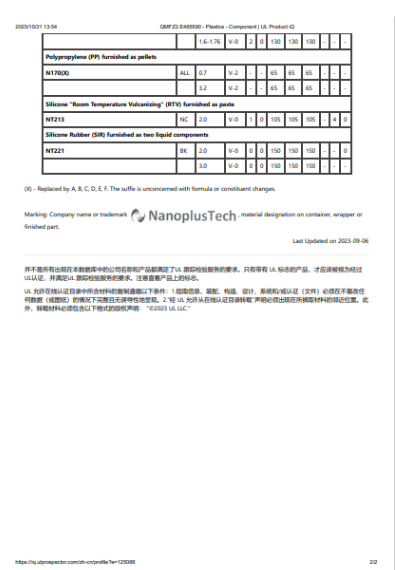

The masterbatch of this product includes PA6 and PPS, with thermal conductivity (0.8~7W/m·K average), easy molding and high cost performance. It has both high thermal conductivity and low density, saving weight and cost.

The thermal paste produced stably by the company is a thermal interface material (TIM) with extremely high thermal conductivity. Its high thermal conductivity comes from the selection of materials, formula, and strict control of the manufacturing process. With its excellent performance, it has become the best interface material required for the heat dissipation interface of electronic appliances such as high-power LED lamps, computer CPUs, GPU high-performance chips, radiators, communication equipment, etc.

| Name | Appearance | Description |

| White plastic pellets |  |

In addition to the original color, the white insulation series can be adjusted to gray to replace spray paint and electroplating products. This technology is the leading level in the industry. |

| Black plastic pellets |  |

There are two types of black series: insulating and conductive. The insulating effect can be achieved by coating the surface with different colors. |

| Thermal paste |  |

This product is a thermal interface material (TIM), which is coated between electronic components such as various computer CPUs & GUPs, high-power chips and LED lamps, etc., and the heat dissipation base to fill the gaps to form a good heat conduction channel, allowing the device to work The temperature is reduced below the critical point to extend the service life of components. |

| No | Name | Type | Application Number | Patentee | Application date | Authorization announcement number |

| 1 | A granulation cooling device for plastic particle production | Utility model | 2022229019222 | Kunshan Nano | 2022/10/21 | CN219054950U |

| 2 | A cleaning and drying machine for plastic particle production | Utility model | 2022224505116 | Kunshan Nano | 2022/9/9 | CN218486715U |

| 3 | A plastic particle packaging bag palletizing and shaping machine | Utility model | 2022221633644 | Kunshan Nano | 2022/8/15 | N218288395U |

| 4 | A kind of separation and dust removal equipment for plastic particles | Utility model | 2022221638154 | Kunshan Nano | 2022/8/15 | CN218614894U |

| 5 | A rapid drying device for plastic particles | Utility model | 2021234573257 | Kunshan Nano | 2021/12/30 | CN217373021U |

| 6 | A plastic particle dust collection device | Utility model | 2021233622788 | Kunshan Nano | 2021/12/25 | CN217017770U |

| 7 | A pipe lifting device for plastic particles | Utility model | 2021232574128 | Kunshan Nano | 2021/12/17 | CN216862714U |

| 8 | A plastic particle quality detection device | Utility model | 2021232020165 | Kunshan Nano | 2021/12/17 | CN217033328U |

| 9 | A new type of conveyor mesh belt | Utility model | 2021208435308 | Kunshan Nano | 2021/4/22 | CN215754600U |

| 10 | A new type of granulator vacuum tank | Utility model | 2021208443361 | Kunshan Nano | 2021/4/22 | CN215256710U |

Philips

Osram

General Electric

Shengdi Lighting

Lenovo

ASUS

Midea

TCP

NVC Lighting

Case acceptance process

- Contact the sales representative directly (contact window below)

- Add the company's WeChat account 18913148285 (same as WeChat account) for consultation, and then recommend corresponding services according to customer needs

- If customers have inquiries about information attachments, they can send them to the email lulu@nanoplustech.cn

Business representative:

Tang Ningqi 18626183953