Heavy metal sludge recycling treatment

Heavy metal sludge recycling treatment

With the development trend of ESG, organizational inquiry and product carbon footprint are the basic operations for enterprises to prepare for carbon reduction. Beyond the boundaries of enterprise carbon inventory, including carbon emissions of raw materials, waste processing and finished products, more and more attention will be paid. The treatment of heavy metal sludge waste has always been a problem for traditional industries, especially the machinery and chemical industries. However, if heavy metal sludge can be concentrated and reused to become a part of the circular economy, the finished product can replace mine mining and the reuse process can reduce sludge. The amount of solidified landfills can provide carbon reduction benefits to customers or suppliers.

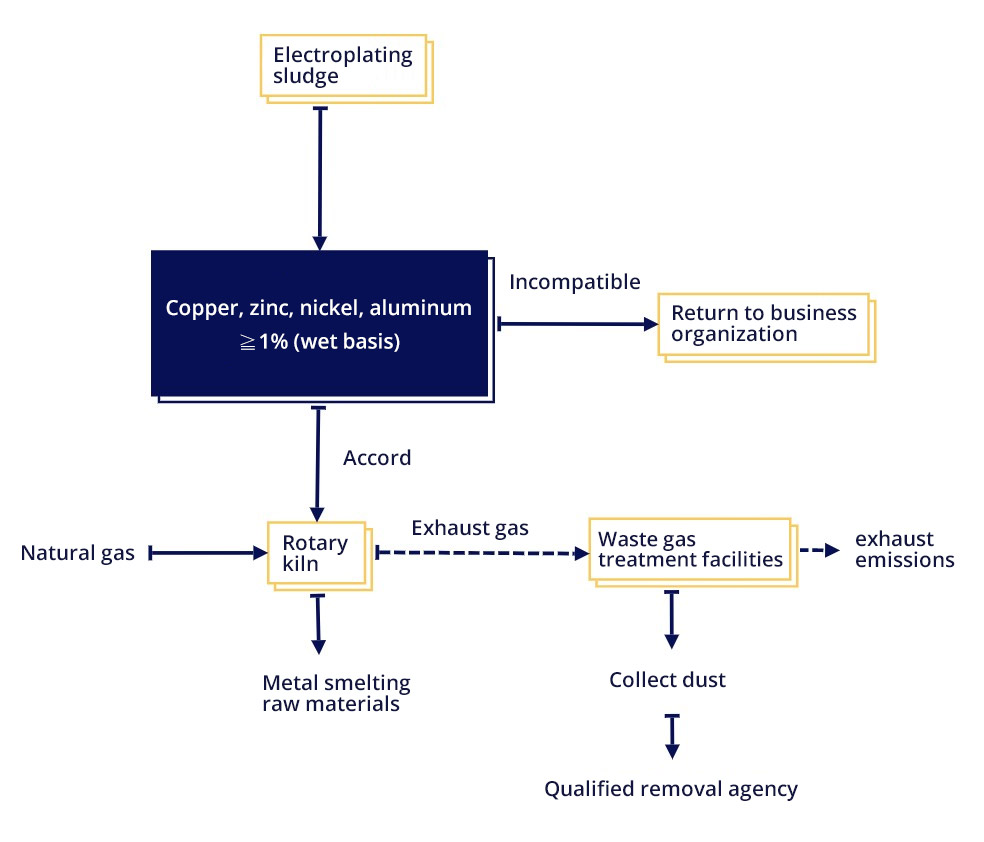

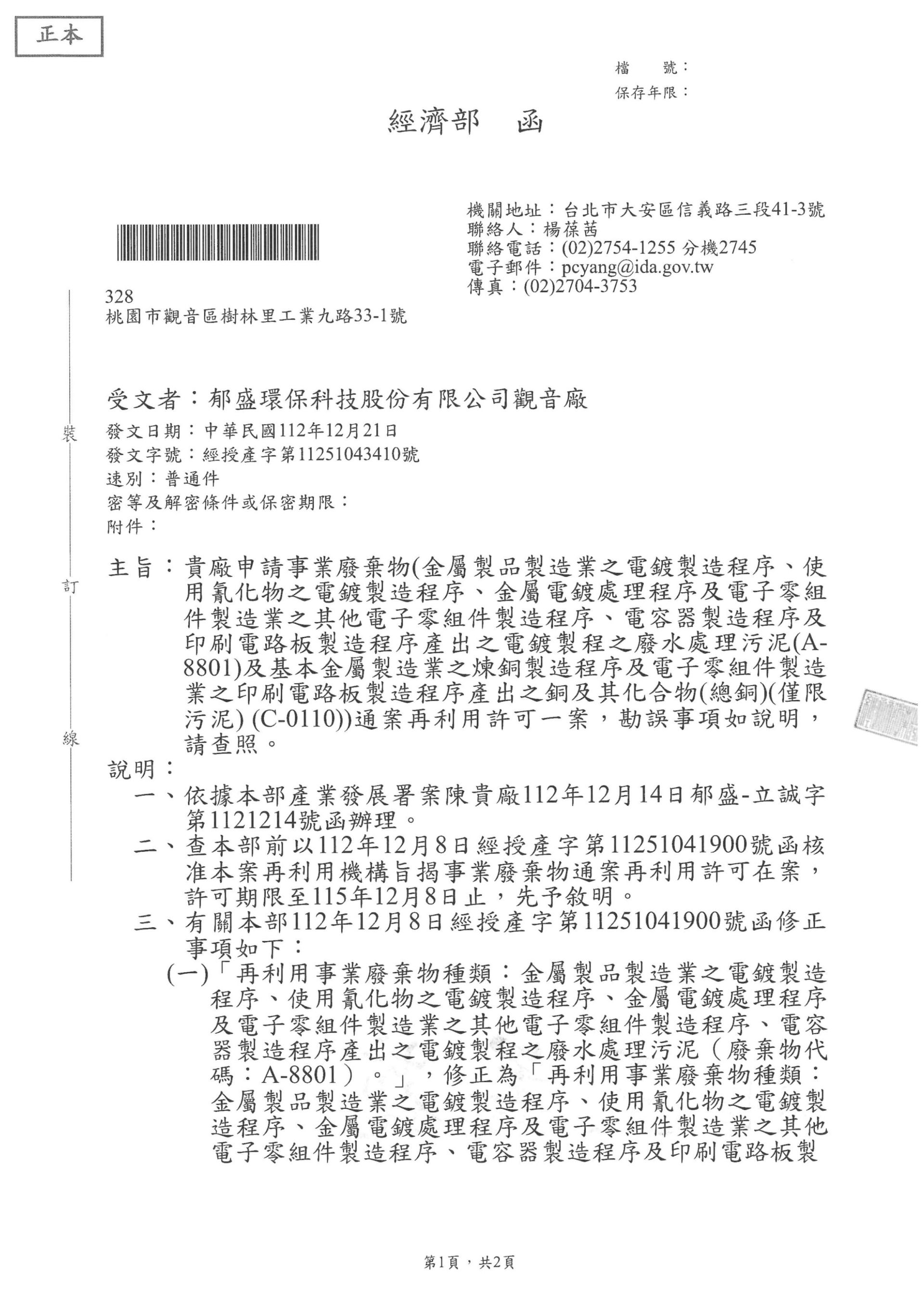

Our company's reuse facilities (rotary drying furnace equipment) obtained a general reuse permit in 2022. It can collect heavy metal sludge from major industrial areas and obtain high metal content finished products through the calcining process. It can be smelted and reduced into metals by downstream merchants to achieve the goal of circular economy.

Professional skills

Recycling facilities: rotary drying oven

Facility specifications: 2.2m(0)x20m(L)

Processing capacity: 3.13 metric tons/hour x 24 hours x 25 working days

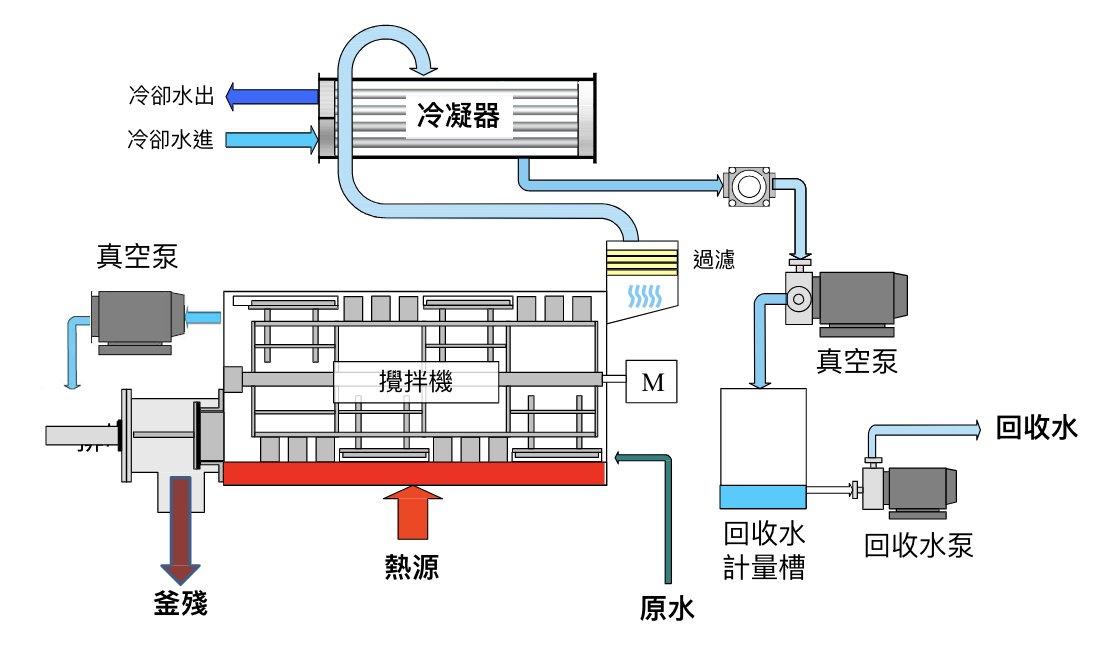

Purpose: To use rotary dry combustion to remove water and combustible components from electroculture sludge, which has achieved the purpose of waste elimination and increased the content of valuable metals

Fuel: natural gas

Operating temperature: 300~900℃

Making process

Nanmeite Technology

Huashang Technology

YAGEO

JAE

Kaiyang Hardware

Service principal

Yusheng Environmental Protection Technology Co., Ltd.Go Link

Service process and consultation

1. Case acceptance process

1. Origin sample testing before signing the contract.

2. Arrange the sludge with the same characteristics, mainly recovering valuable metals, to enter the plant.

3. The sludge entering the factory carried by the clean-up vehicles will be sampled bag by bag, and a set of samples will be taken from each business unit for testing.

4. The sludge entering the plant is marked with the waste code, origin, date of entry, and quantity bag by bag, and then placed in the storage area.

5. The weight of each bag of sludge must be weighed and recorded before entering the process for reuse.

6. Process temperature monitoring and speed control.

7. Monitoring of the operation of air pollution control facilities and real-time monitoring and connection of pollutant emissions.

8. Finished products are sampled and tested per package according to the production sequence.

When the finished product is shipped, we will jointly take samples for testing with the buyer. Each package of the cabinet will be sampled and a set of samples will be taken for testing

2. Business representative and contact information:

Yusheng Environmental Protection Technology Co., Ltd.

Associate Manager-KK Chen Guanhong

Assistant-Alisa Lai Jili

TEL:03-4832875

FAX: 03-483283

Address: 33- Gongye 9th Road, Guanyin District, Taoyuan City No. 1